There are two solutions we have used to "fix" the common fuel starve issue on the S197 Mustang, which occurs on long left hand turns on a road course as grip levels go up. We fought this on both our S197 and S550 road race cars, and with good 200TW tires fuel starvation happens at 1/2 tank or less. With big Hoosiers and/or aero grip added, it can happen on long turns at even 3/4 tank.

This won't happen on "every" left hand turn, and not to every driver. If you are timid (slow), or use really crappy tires, it might never happen to you. On our 2011 GT we just ran with the tank full for every Time Trial session, and we ran fairly short sessions. We ran this car in a class where we needed ballast to make weight (we ran NASA TT3 class at 3802 pounds - to be able to get a bonus for higher weight in this power-to-weight class), so it wasn't an issue - unless we forgot to refuel for a session.

Both examples of the "fix" below are from different S197 race cars we built for customers. We will update this when we do the same to our current 2015 GT S550 Mustang build (which will use an external surge tank).

Example 1 - External Surge Tank

We performed this solution on Jamie Beck's 2013 Mustang GT, which was prepped for NASA ST2 and ST3 competition. It runs 315/30/18 Hoosiers at all four corners + has real aero, and would fuel starve under 1/2 tank in long left hand turns.

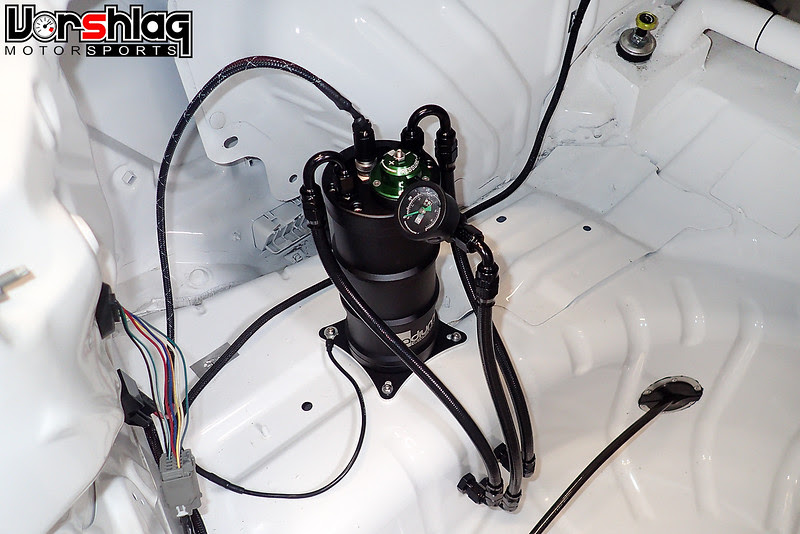

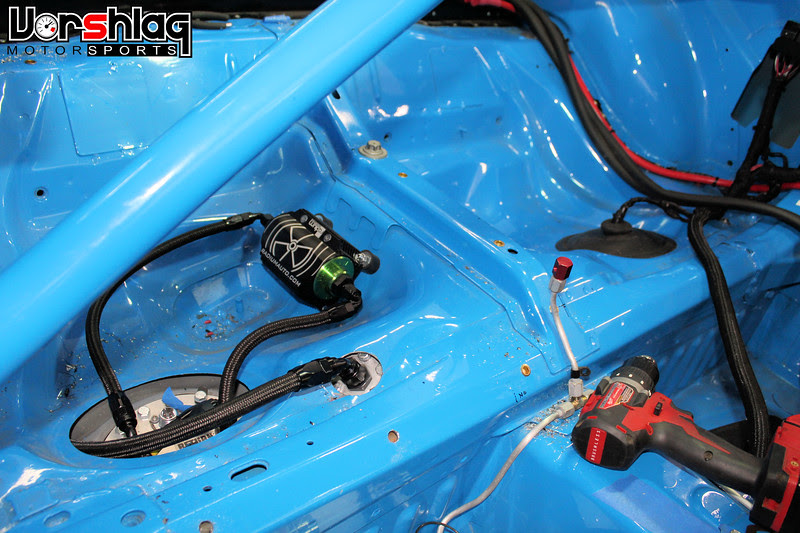

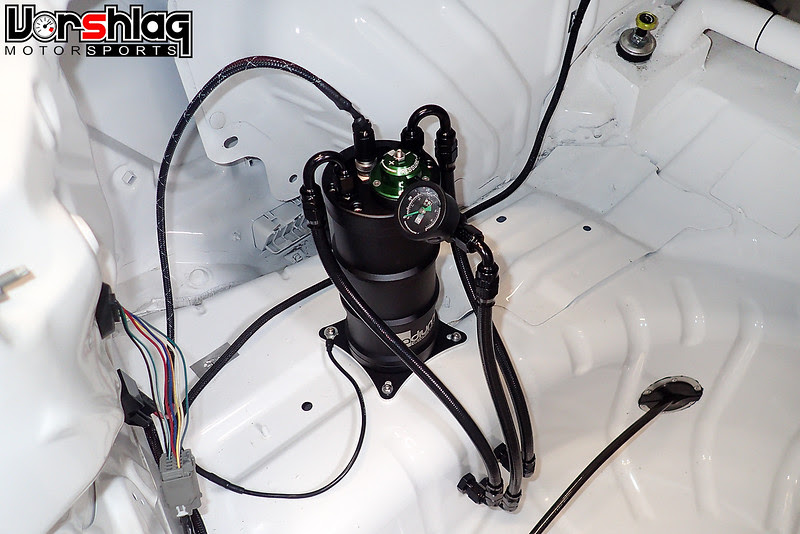

On his car, which uses the OEM computer and wiring, we installed this Radium Engineering remote surge tank with an internal pump and built in fuel pressure regulator. We kept the stock fuel pump in the stock fuel tank.

We tried to minimize the modifications to this fairly stock drivetrain and fuel system. We started by unclipping the OEM plastic fuel lines and dropping the tank.

We then converted the stock fuel pump drop in module to use AN -6 braided lines and Fragola fittings. The stock in-tank pump acts as a lift pump to feed the surge tank. There is a return "overflow" line from the surge tank that dumps excess fuel back into the OEM fuel tank.

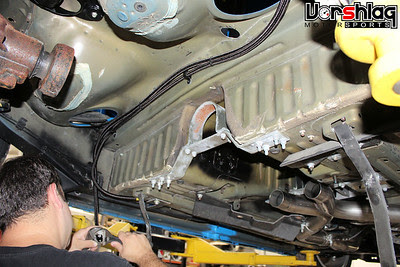

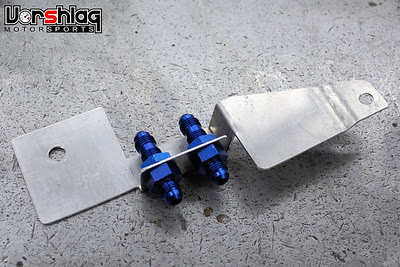

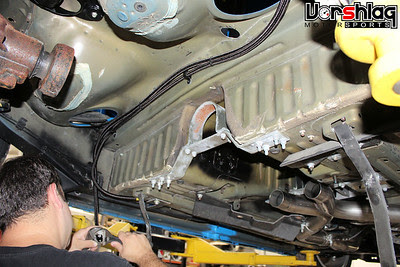

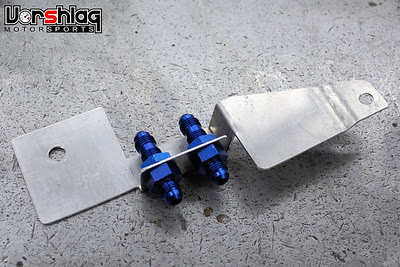

These two lines (lift pump feed and overflow return) go from the tank (shown above) to a series of bulkhead fittings in the trunk floor.

The 3rd line is the high pressure feed line from the surge tank heading to the engine bay. Like the OEM system, this feed line "dead heads" to the fuel rail on the engine, as it is regulated at the surge tank. Many "race car" fuel systems will utilize a feed and return line from the engine bay, with the regulator at the fuel rail of the engine. Again - we wanted to keep this as close to OEM as possible.

The way this works is the stock lift pump feeds fuel to the surge tank, which stays full. The pump inside the surge tank is always covered in fuel and it feeds the engine. Any "overflow" of fuel in the surge tank returns to the stock fuel tank. We did this work on his car in Feb 2018 and Jamie ran this car soon after at MSR Cresson in MArch 2018 - with no more fuel starve issues.

Example 2 - FIA Fuel Cell with Internal Surge Tank

This example is more elaborate and expensive. On this 2010 Mustang GT "Spec Iron" car we were tasked with moving it up to NASA American Iron and ST2 classes. It fuel starves on long left hand turns, which I experienced when driving it at MSR Cresson also.

Most modern cars use an OEM plastic "saddle" style fuel tank, and the 2011-14 Mustangs use one like this. This design "crashes" well in crash tests. But it cannot be converted into a fuel cell. The STEEL saddle tank in earlier S197 (2005-2010) Mustangs is the same size and shape but it CAN be converted into a fuel cell and used in the stock location with minimal changes.

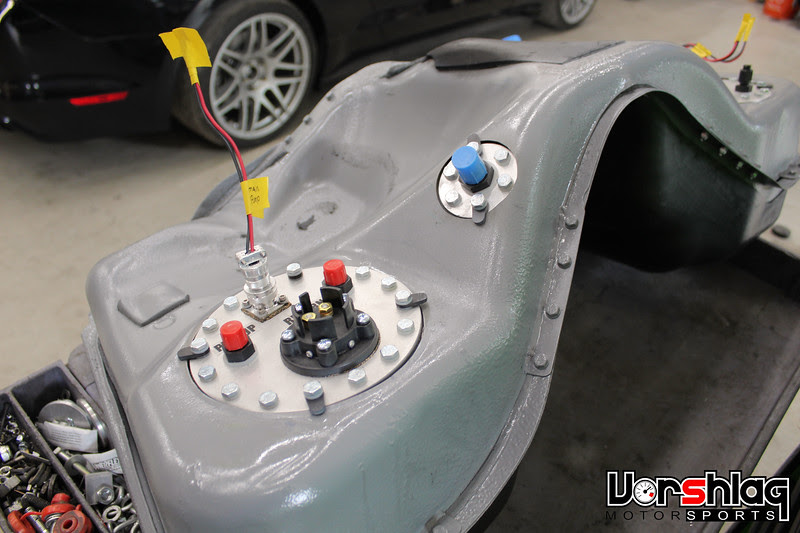

In July 2019 we removed, cleaned, and boxed up this steel 2010 tank and sent it to Pyrotect Fuel Cells for conversion into an FIA fuel cell with ballistic bladder and internal surge tank.

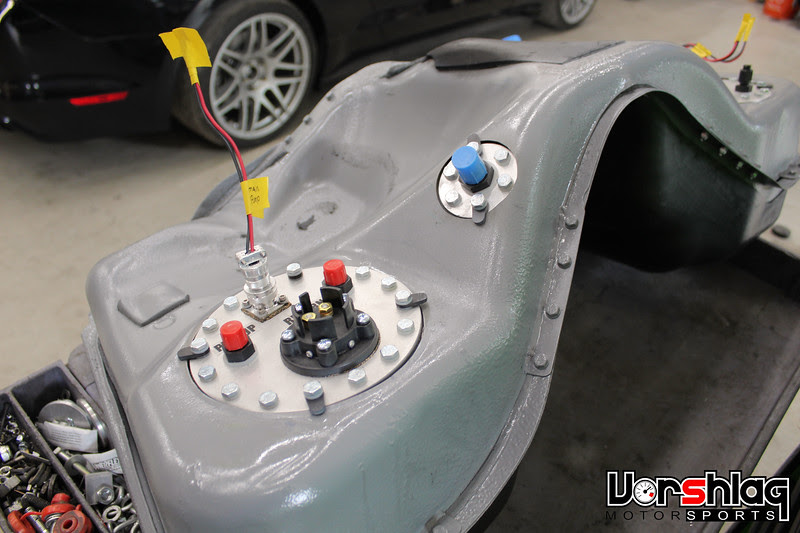

In May of 2020 (yes it took that long) this was returned to us converted - they cut the steel tank in half and now it is the "can" for the internal fuel cell bladder. Pyrotect added flanges to the upper half and we added bolts to connect the upper and lower sections of the steel can.

This setup now has fuel pumps in both "saddles" - with the main pump shown above. There is an internal float sensor on the "secondary" saddle side that shuts the secondary (lift) pump off when it is empty, so it doesn't just "run dry".

We had to remove the stock rollover / "check valve" from the stock filler line (the cell has this built in), plus convert the fuel filler neck to a new size with the big 2" to 1.25" "reducers" shown above right.

The fuel cell mounts just like the tank it was made from - under the back seat, in the middle of the chassis - the BEST spot on a race. We had to route the new fuel lines around the tank, so there were some tricks there.

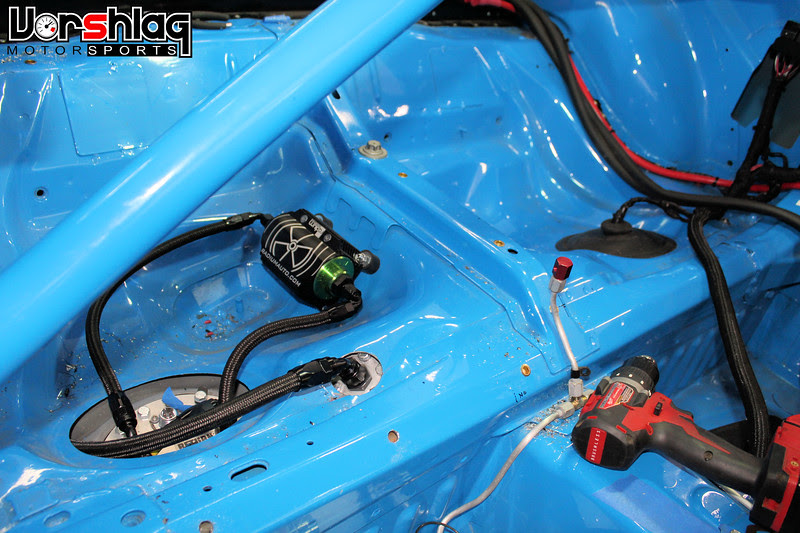

Routing the lines to the main fuel cell bulkhead under the right side rear seat was tricky, and we had to come up into the cabin to "make the turn". So we put a Radium Engineering fuel filter in the back seat area, and also cut a hoile for the rollover vent, which was added to the cell. That line and the fuel feed line to/from the filter route back into the "hole" in the back seat, then head forward.

We completely replumbed the fuel system on this car, as we were also swapping from a 4.6 3V engine to a 4V Gen II Coyote 5.0L. This system uses AN style hoses and hard lines from the rear to the front, with a feed and return line.

The fuel system is regulated by this Holley regulator in the engine bay, which then feeds into the stock 5.0L fuel rail.

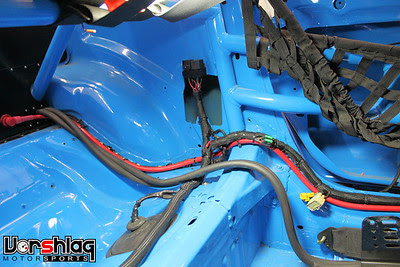

The two fuel pumps from Pyrotect are controlled by solid state relays that are controlled by the ECM. We wired in all of that at our shop.

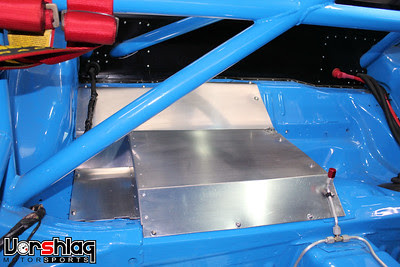

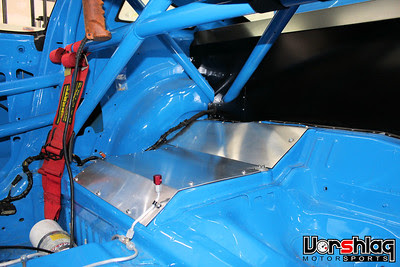

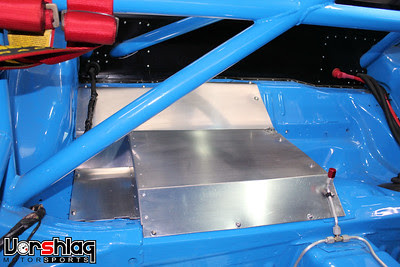

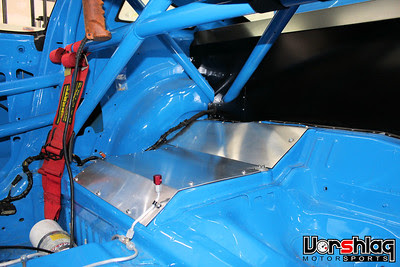

To finish this setup we made this aluminum bulkhead cover for the back seat fuel lines and filter, to keep the cabin area separate from any possible fuel fumes or fire. The fuel cell was not cheap, and this setup would normally only be used on a dedicated street car.

We understand that neither solution is "bolt on" and requires some real plumbing and wiring skills, but we do not know of a "plug and play" surge tank kit on the market. Most folks would want to have this type of work done at a qualified motorsports shop familiar with fuel systems, AN lines, and wiring.

Hope this helps!

This won't happen on "every" left hand turn, and not to every driver. If you are timid (slow), or use really crappy tires, it might never happen to you. On our 2011 GT we just ran with the tank full for every Time Trial session, and we ran fairly short sessions. We ran this car in a class where we needed ballast to make weight (we ran NASA TT3 class at 3802 pounds - to be able to get a bonus for higher weight in this power-to-weight class), so it wasn't an issue - unless we forgot to refuel for a session.

Both examples of the "fix" below are from different S197 race cars we built for customers. We will update this when we do the same to our current 2015 GT S550 Mustang build (which will use an external surge tank).

Example 1 - External Surge Tank

We performed this solution on Jamie Beck's 2013 Mustang GT, which was prepped for NASA ST2 and ST3 competition. It runs 315/30/18 Hoosiers at all four corners + has real aero, and would fuel starve under 1/2 tank in long left hand turns.

On his car, which uses the OEM computer and wiring, we installed this Radium Engineering remote surge tank with an internal pump and built in fuel pressure regulator. We kept the stock fuel pump in the stock fuel tank.

We tried to minimize the modifications to this fairly stock drivetrain and fuel system. We started by unclipping the OEM plastic fuel lines and dropping the tank.

We then converted the stock fuel pump drop in module to use AN -6 braided lines and Fragola fittings. The stock in-tank pump acts as a lift pump to feed the surge tank. There is a return "overflow" line from the surge tank that dumps excess fuel back into the OEM fuel tank.

These two lines (lift pump feed and overflow return) go from the tank (shown above) to a series of bulkhead fittings in the trunk floor.

The 3rd line is the high pressure feed line from the surge tank heading to the engine bay. Like the OEM system, this feed line "dead heads" to the fuel rail on the engine, as it is regulated at the surge tank. Many "race car" fuel systems will utilize a feed and return line from the engine bay, with the regulator at the fuel rail of the engine. Again - we wanted to keep this as close to OEM as possible.

The way this works is the stock lift pump feeds fuel to the surge tank, which stays full. The pump inside the surge tank is always covered in fuel and it feeds the engine. Any "overflow" of fuel in the surge tank returns to the stock fuel tank. We did this work on his car in Feb 2018 and Jamie ran this car soon after at MSR Cresson in MArch 2018 - with no more fuel starve issues.

Example 2 - FIA Fuel Cell with Internal Surge Tank

This example is more elaborate and expensive. On this 2010 Mustang GT "Spec Iron" car we were tasked with moving it up to NASA American Iron and ST2 classes. It fuel starves on long left hand turns, which I experienced when driving it at MSR Cresson also.

Most modern cars use an OEM plastic "saddle" style fuel tank, and the 2011-14 Mustangs use one like this. This design "crashes" well in crash tests. But it cannot be converted into a fuel cell. The STEEL saddle tank in earlier S197 (2005-2010) Mustangs is the same size and shape but it CAN be converted into a fuel cell and used in the stock location with minimal changes.

In July 2019 we removed, cleaned, and boxed up this steel 2010 tank and sent it to Pyrotect Fuel Cells for conversion into an FIA fuel cell with ballistic bladder and internal surge tank.

In May of 2020 (yes it took that long) this was returned to us converted - they cut the steel tank in half and now it is the "can" for the internal fuel cell bladder. Pyrotect added flanges to the upper half and we added bolts to connect the upper and lower sections of the steel can.

This setup now has fuel pumps in both "saddles" - with the main pump shown above. There is an internal float sensor on the "secondary" saddle side that shuts the secondary (lift) pump off when it is empty, so it doesn't just "run dry".

We had to remove the stock rollover / "check valve" from the stock filler line (the cell has this built in), plus convert the fuel filler neck to a new size with the big 2" to 1.25" "reducers" shown above right.

The fuel cell mounts just like the tank it was made from - under the back seat, in the middle of the chassis - the BEST spot on a race. We had to route the new fuel lines around the tank, so there were some tricks there.

Routing the lines to the main fuel cell bulkhead under the right side rear seat was tricky, and we had to come up into the cabin to "make the turn". So we put a Radium Engineering fuel filter in the back seat area, and also cut a hoile for the rollover vent, which was added to the cell. That line and the fuel feed line to/from the filter route back into the "hole" in the back seat, then head forward.

We completely replumbed the fuel system on this car, as we were also swapping from a 4.6 3V engine to a 4V Gen II Coyote 5.0L. This system uses AN style hoses and hard lines from the rear to the front, with a feed and return line.

The fuel system is regulated by this Holley regulator in the engine bay, which then feeds into the stock 5.0L fuel rail.

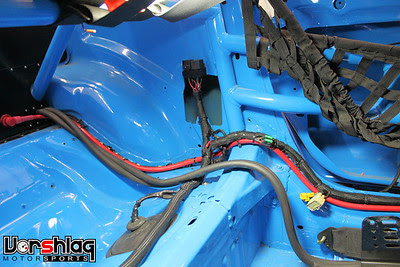

The two fuel pumps from Pyrotect are controlled by solid state relays that are controlled by the ECM. We wired in all of that at our shop.

To finish this setup we made this aluminum bulkhead cover for the back seat fuel lines and filter, to keep the cabin area separate from any possible fuel fumes or fire. The fuel cell was not cheap, and this setup would normally only be used on a dedicated street car.

We understand that neither solution is "bolt on" and requires some real plumbing and wiring skills, but we do not know of a "plug and play" surge tank kit on the market. Most folks would want to have this type of work done at a qualified motorsports shop familiar with fuel systems, AN lines, and wiring.

Hope this helps!