This typical 3 day job that includes:

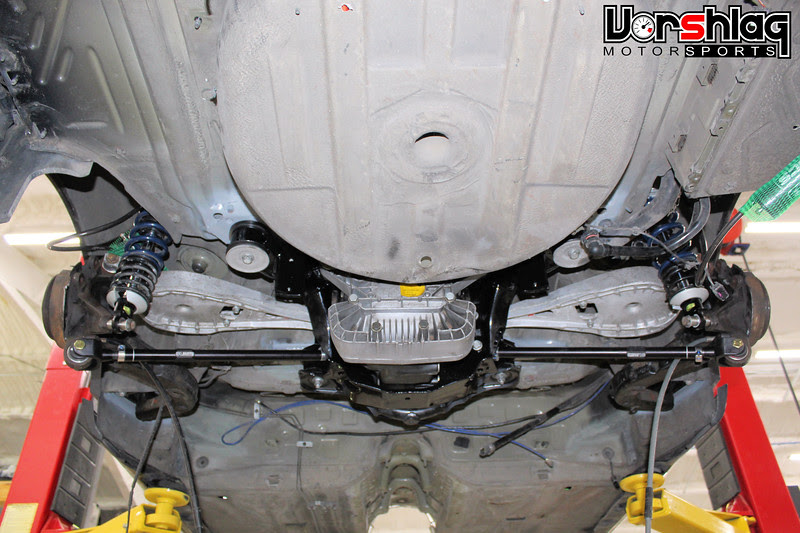

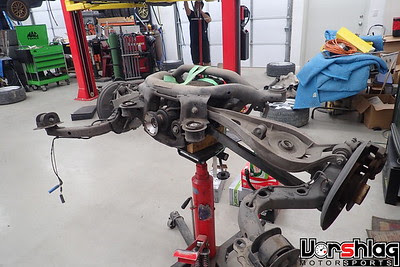

1. Removing the exhaust, driveshaft, then the entire rear subframe assembly.

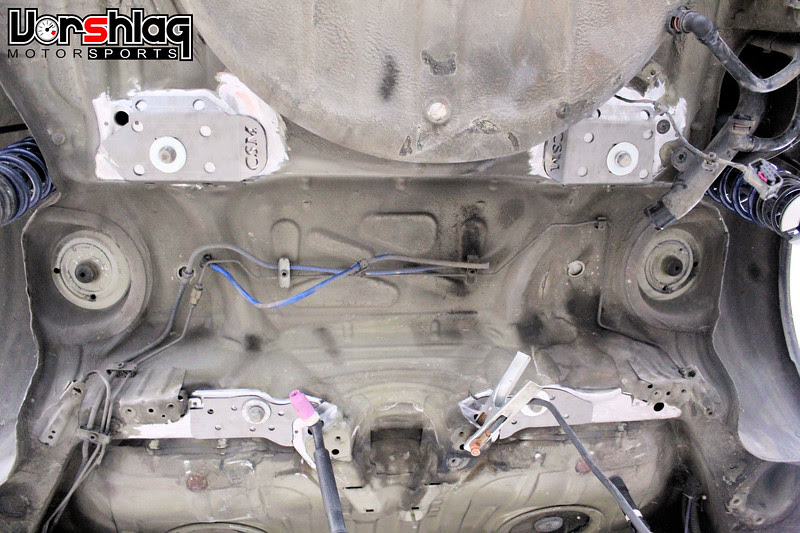

2. Getting all of the undercoating out of the way (this part REALLY sucks)

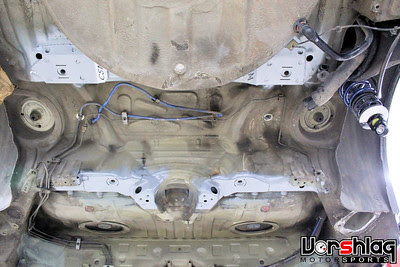

3. Finding and drill-stopping all cracks, welding up all cracks

4. TIG welding (overhead welding sucks) in the reinforcement kit then prime / seam seal / and paint every area touched

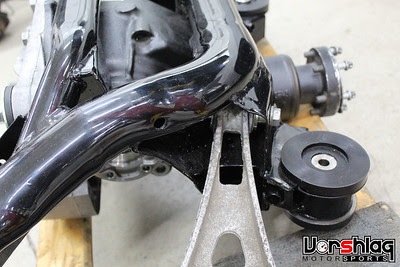

5. Replacing the subframe mount bushings with poly versions

6. Replacing the diff mount bushings with poly versions

7. Replacing the RTAB bushings

8. Putting it all back together.

This is a "not fun" job but one that we seem to be uniquely qualified for. Lots of shops send us this work because of how we weld it in (the rod and TIG technique), our prep / painting work, and nobody else wants to do it. Or can seem to do it well.

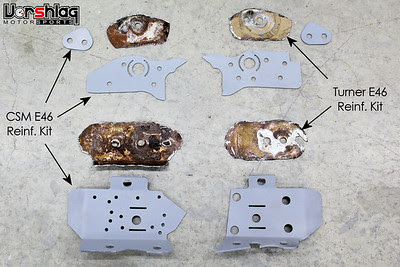

WE HATE THIS JOB. We charge extra for rusty cars, cars with previous (shitty) repair attempts, or cars with crash damage. But we still offer a lifetime guarantee on our work - and have done this job on E46 cars 75-100 times? We've even had to *cut out* several "BMW repaired" and other shops' "repairs" to do it right, including this recent one above where the little Turner plates were not doing the job (not welded, primed, and rusted to hell).

WE HATE THIS JOB. It is very fiddly, the welding technique is critical, and the prep work is ultra important.

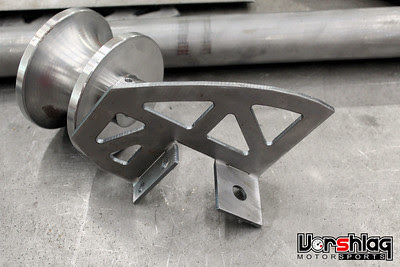

We offer some optional reinforcements that we cut in-house for the trunk floor and RTAB pockets, for people who just HATE money. But when the car is damaged in these spots, it is usually necessary.

Our typical estimate has some OPTIONAL things that we normally end up doing - the subframe mounts, diff mounts, and RTABs. You do that yourself, you save $$ - but we have the whole damn subframe out to do the welding, so it usually gets bundled. This bushing work gobbles up a solid day on its own, and we have $2000 in special tools we have purchased or built to make it faster. There is no short cut - that job sucks, too. We have a new sealed spherical that replaces the RTAB bushing with zero downsides, which is nice.

Will we find other things while we are in there? Who knows - driveshaft guibo, worn suspension bushings, driveshaft center bearing - it's all possible. We always take copious pics and let the customer decide how far we go into repairs.

We have yet to find an E46 that wasn't cracked, and we've seen some really bad ones - these cracks have to be "drill stopped" (see above) to keep them from propagating, then stitch welded back together. THEN covered up with the giant reinforcement plates. We won't know how bad it is until we drop the subframe, but we put enough hours in our typical estimate to cover the typical repair.

Call around - its a super nasty job and if you can find anyone better qualified for a better price, rock on - we won't shed a TEAR to avoid this work. We don't enjoy these jobs because it makes a total mess of the shop for days, and if there are other things we find the job can snowball into a week of repairs.

Enjoy!